Tungsten-lanthanum alloy

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 5pcs |

| Transportation: | Ocean,Air,Express |

Attributes

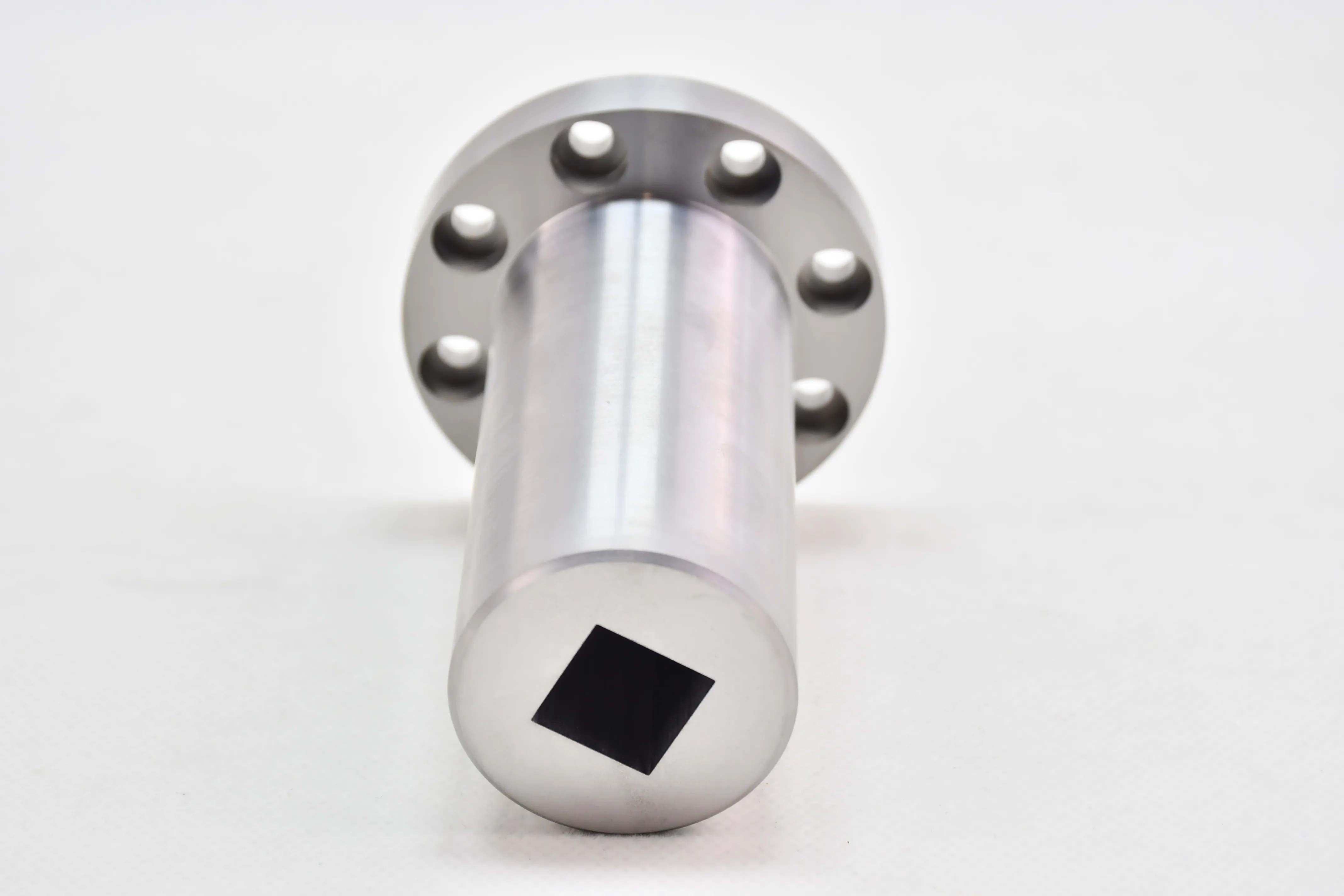

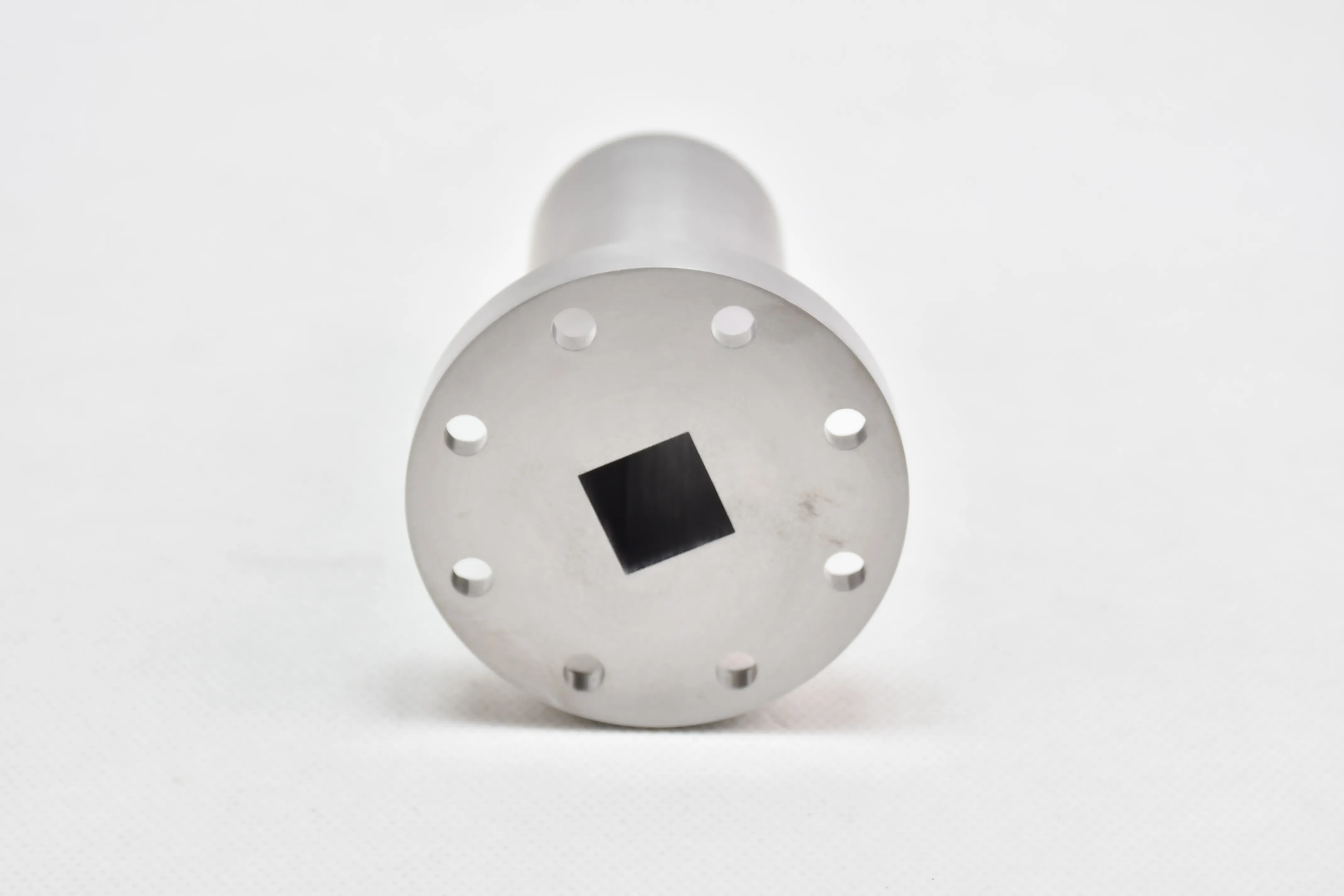

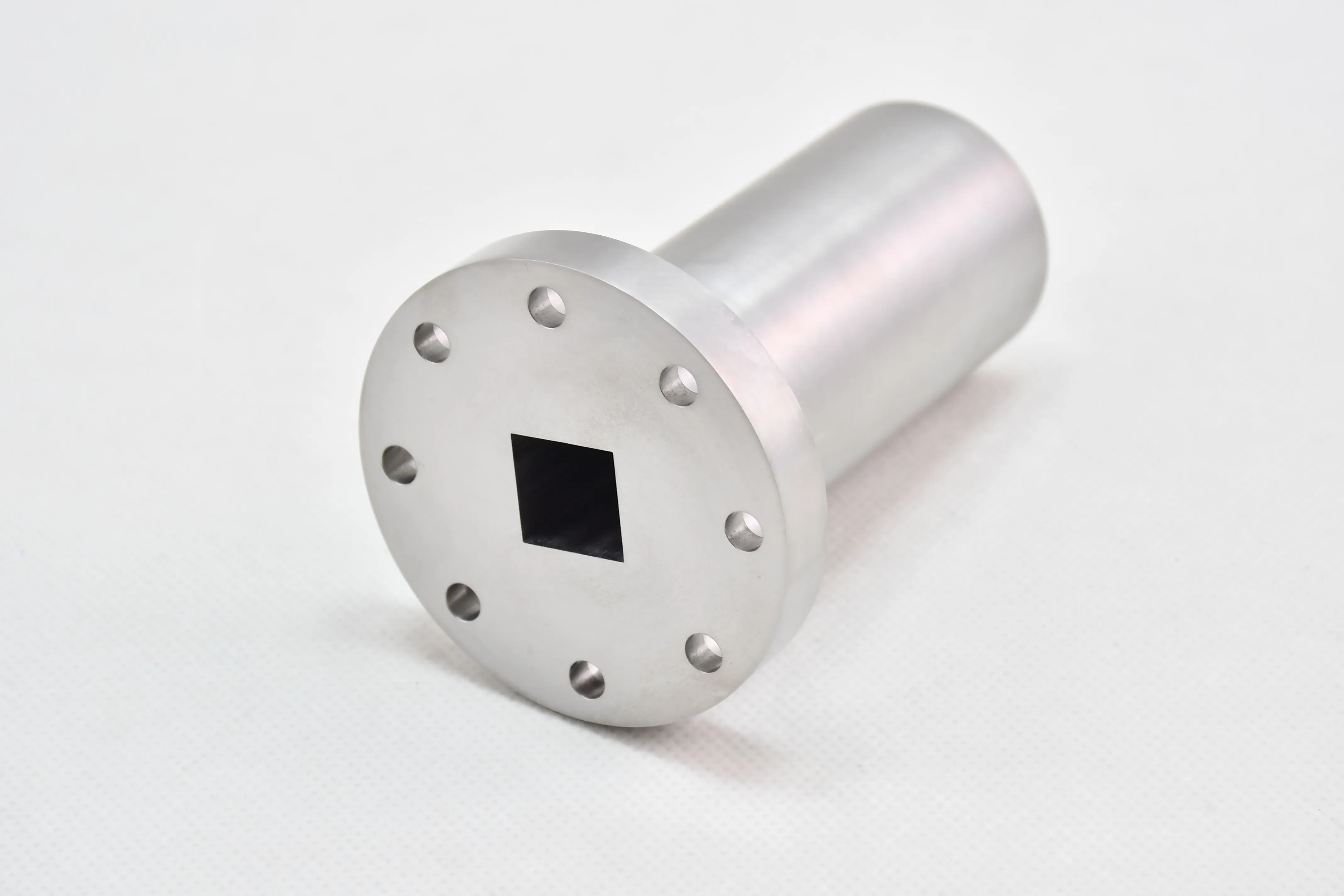

Model No.: JDTG-CM-059

Brand: ZZJD

Place Of Origin: China

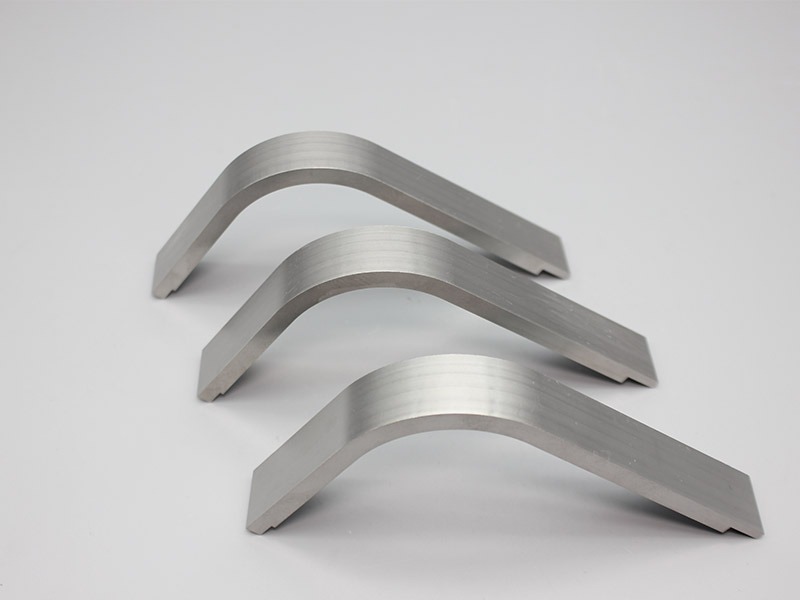

Size: Custom-made

Material: 85-99% Tungsten

Denstiy: 15.8-18.75 g/cm3

Surface: Sintered, Forged, Grounded

PACKAGING & DELIVERY

Selling Units : PCS

Package Type : Standard export packing

DESCRIPTION

Tungsten-lanthanum alloy is a composite material with excellent properties

- Composition and Structure:

- It is a composite material with metallic tungsten as the matrix and nanoscale lanthanum trioxide (La₂O₃) incorporated to form a dispersion-strengthening phase. The content of La₂O₃ is controlled within the range of 0.5%-2.5% (mass fraction), and the particle size is concentrated at 20-100nm, distributed in a chain shape along the grain boundaries.

- Production Process:

- It is usually prepared by powder metallurgy and flash sintering processes. The preparation process includes three stages. First, ammonium paratungstate and lanthanum nitrate are mixed in a liquid phase, and after vacuum drying, a composite powder is obtained. Then, tape casting is carried out, and the solid content of the slurry is maintained at 60%-70%. After drying, flash sintering is carried out at a temperature of 1000-1200°C and a current density of 40-60mA/mm². Finally, plastic processing such as cold rolling and rotary forging is carried out.

-

- Performance Characteristics:

- The alloy has the characteristics of grain refinement and excellent creep resistance. Its recrystallization temperature is increased to above 2200°C. When the La₂O₃ doping amount is 1.0%, the hardness HV can reach 480, which is about 30% higher than that of pure tungsten. The room-temperature bending strength reaches 740-780MPa, and the elongation at break at 500°C is 45% higher than that of traditional tungsten alloys.

- Application Fields:

- It is suitable for high-strength scenarios such as plasma welding electrodes and nuclear fusion device components. For example, the 1.5% lanthanum-tungsten electrode used in argon arc welding has a conductivity close to that of the traditional 2.0% thorium-tungsten electrode, and there is no radioactive pollution. As a candidate material for the ITER project, it can withstand a neutron irradiation dose of 1×10²⁴n/m².

- Appearance:

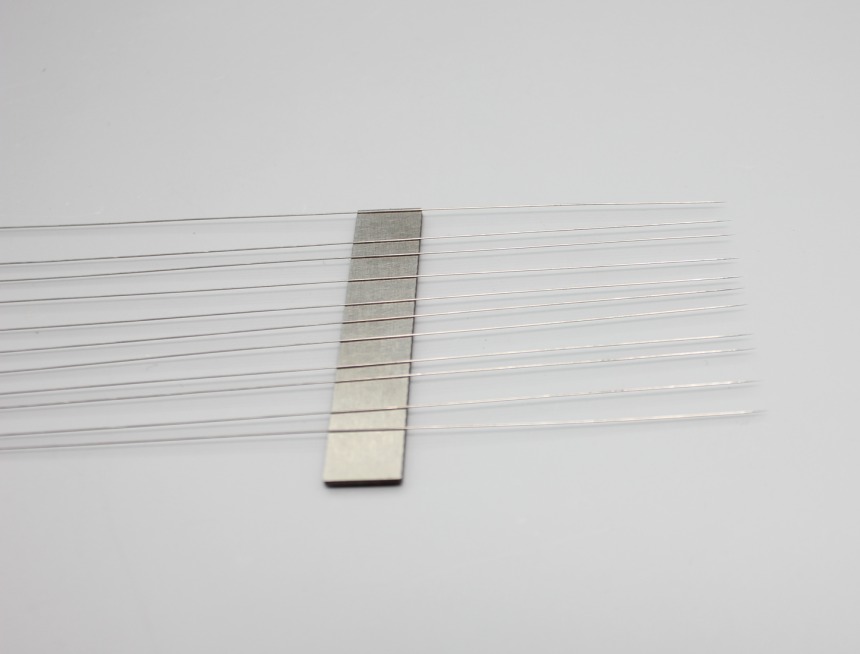

- The tungsten-lanthanum alloy wire prepared by the process is usually a straight wire, and the surface is smooth and shiny.

Customer Questions & Answers

Did not match any questions!

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU