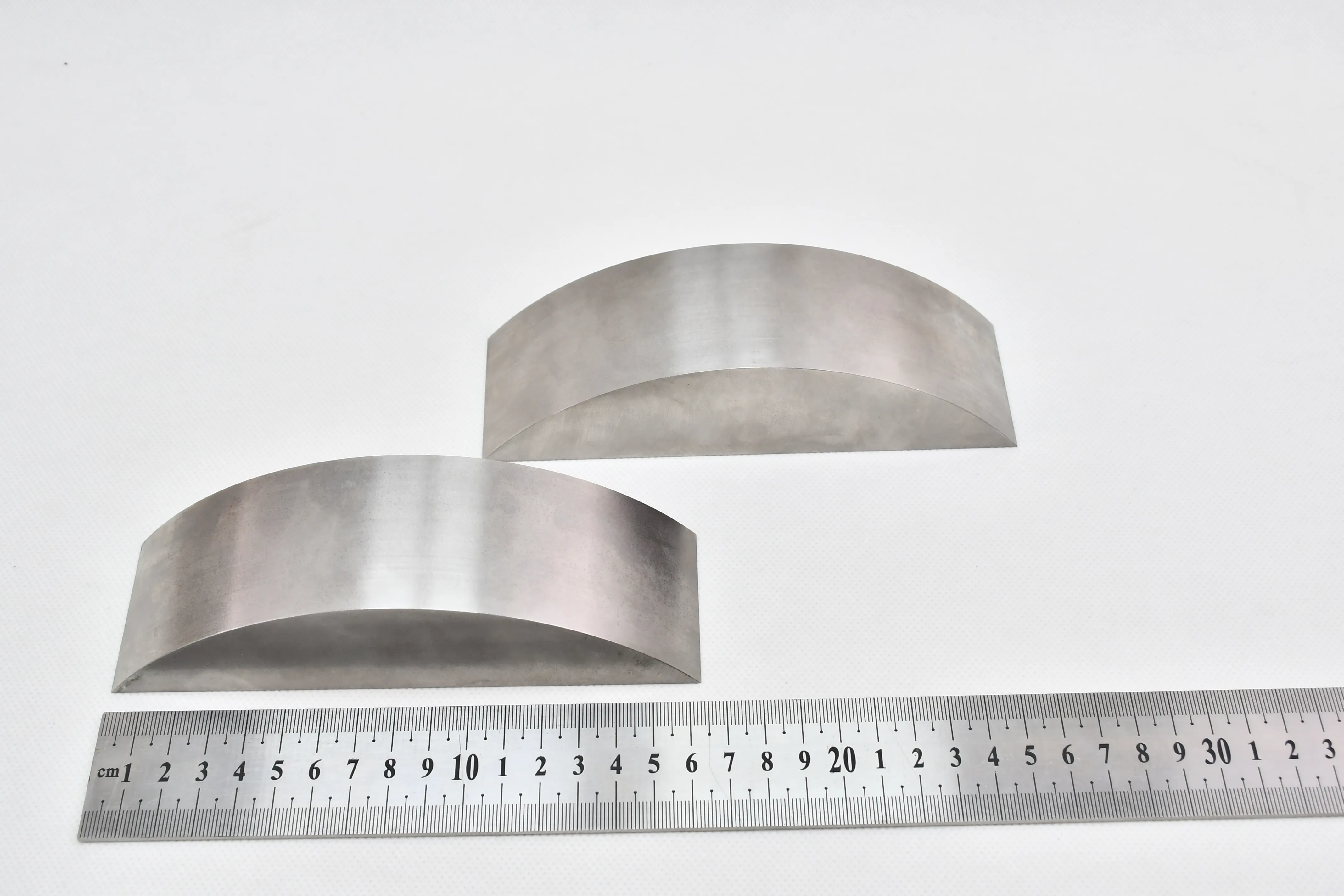

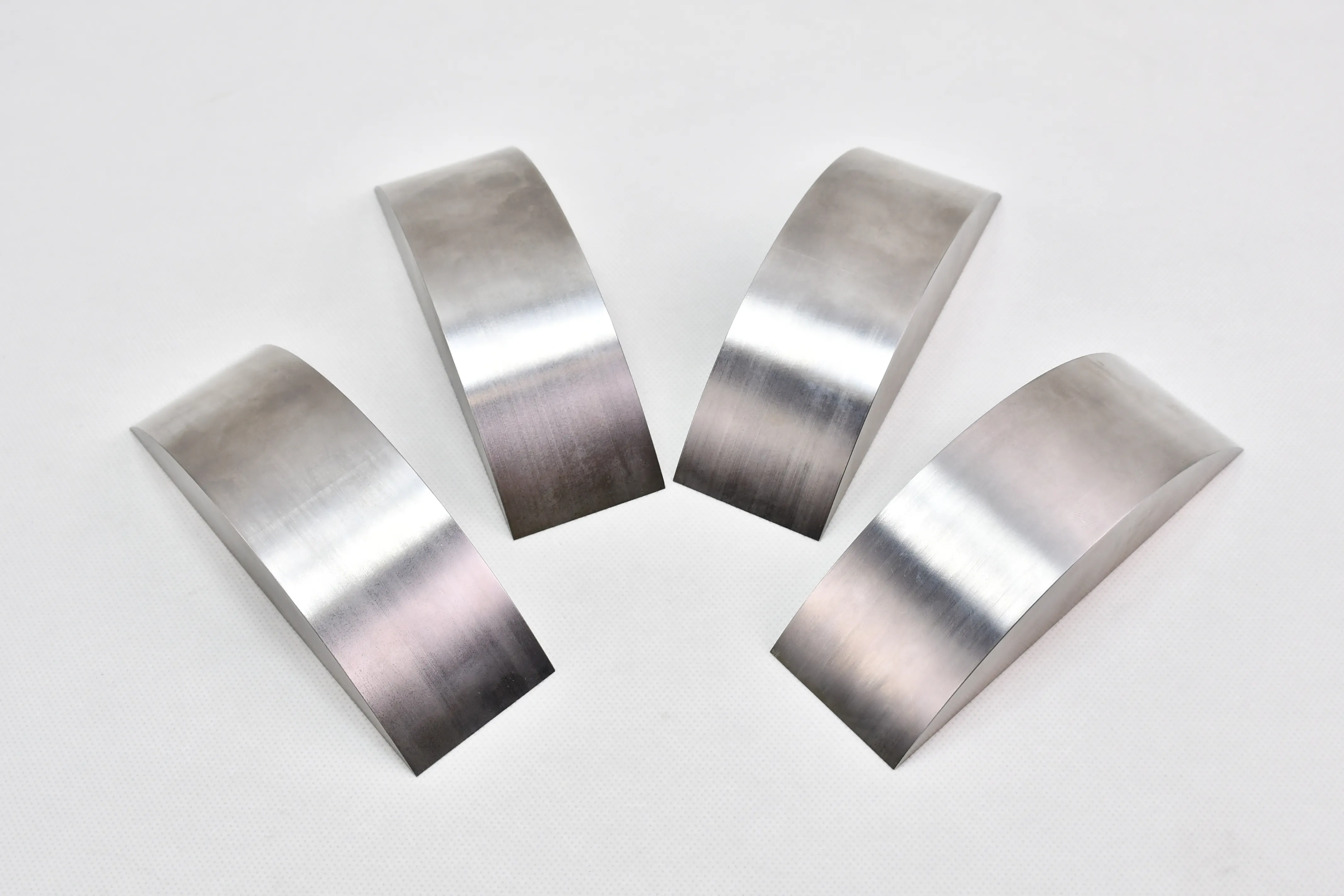

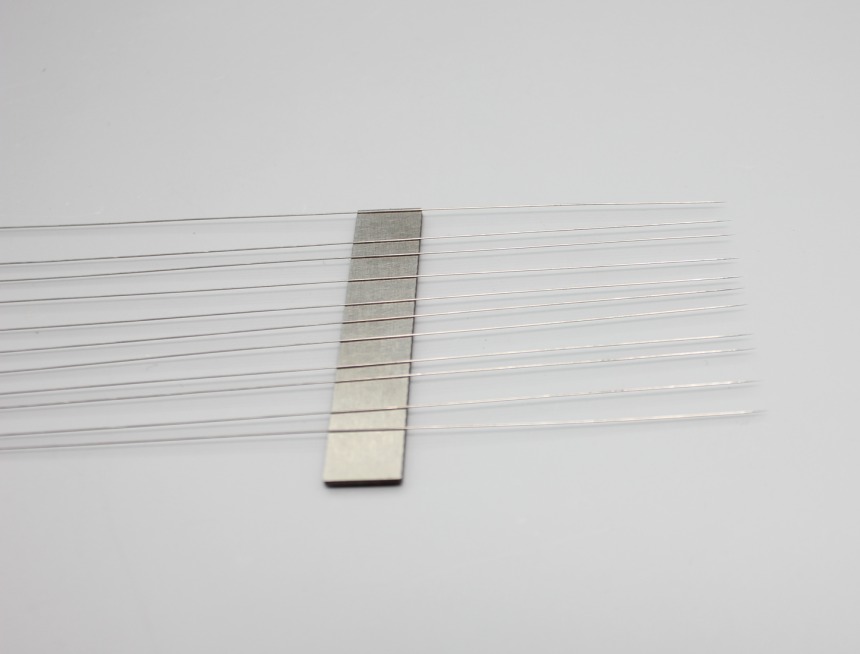

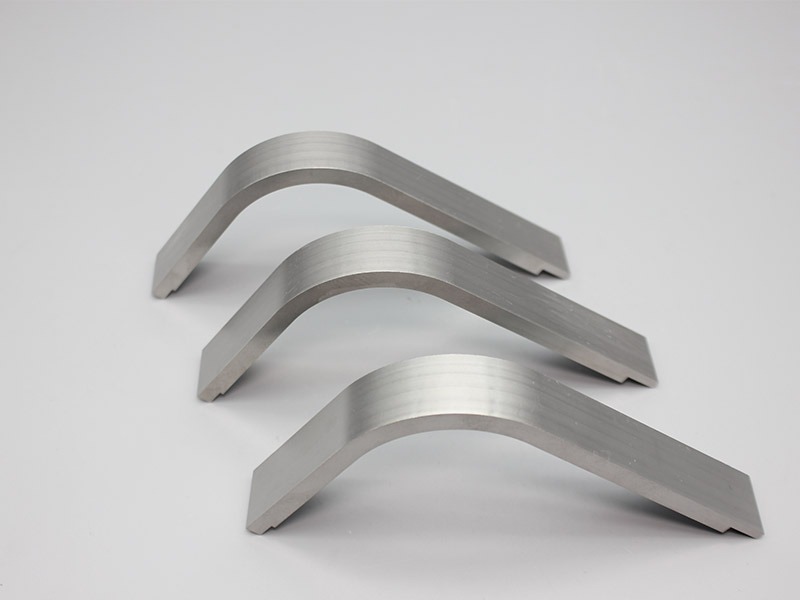

Tungsten heavy alloy counterweight balance

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,FCA,Express Delivery |

| Min. Order: | 10 PCS |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-TC-090

Brand: ZZJD

Place Of Origin: China

Size: Support customiztion

Material: Tungsten

Density: 16~19g/cm³

Surface: Sintering surface, Forged surface, Ground surface

Lead Time: 30 days

PACKAGING & DELIVERY

Selling Units : Kilogram

Package Type : Standard export packing

DESCRIPTION

Tungsten heavy alloy (THA) counterweights deliver ultra - dense, compact balancing for static/dynamic applications, outperforming lead/steel in size - constrained, high - performance scenarios while being far more eco - friendly than lead. They’re made via powder metallurgy (typically WNiFe or WNiCu) with densities of 16.5–18.8 g/cm³, balancing weight, strength, and machinability.

Core Properties & Material Grades of thungsten heavy alloy

|

Property |

Details |

Key Benefit |

|

Density |

16.5–18.8 g/cm³ (1.65–1.85x lead, 2.2x steel) |

Same weight in 30–40% smaller volume for tight designs |

|

Mechanical |

High tensile strength, good ductility, wear/corrosion - resistant |

Withstands dynamic loads (engine crankshafts) and harsh environments |

|

Machinability |

Easy to turn, mill, drill, braze, or shrink - fit |

Custom shapes/sizes for precise center - of - gravity tuning |

|

Environmental |

Non - toxic (vs. lead), low bioaccumulation |

Compliant with RoHS and aquatic protection rules |

|

Magnetic |

Weakly ferromagnetic (standard WNiFe); non - magnetic WNiCu available |

Fits sensitive electronics/avionics |

Applications of tungsten heavy alloy counterweight balance

Aerospace: Rotor/propeller blades, aileron/rudder counterweights, and satellite momentum wheels—small form factor prevents flutter and improves control precision.

Automotive: Crankshaft/flywheel balancing, racing chassis ballast, and EV battery weight distribution—reduces vibration and enhances handling.

Marine: Yacht/sailboat keel ballast and submarine trim weights—high density cuts drag while boosting stability in rough seas.

Precision Instruments: Watch rotor bobs, optical microscope stages, and gyroscopes—micro - sized weights enable ultra - fine balance tuning.

Industrial: Elevator traction weights, drilling logging tool collars, and turbine vibration dampers—extends equipment life by reducing stress loads.

Design & Customization Guide

Weight & density matching: Choose density (17–18.5 g/cm³) based on volume limits—higher density = smaller part for the same mass.

Shape optimization: Machined into bricks, discs, rods, or complex geometries (via isostatic pressing/injection molding) for bolt - on, adhesive, or press - fit installation.

Surface treatments: Electroless nickel plating for corrosion resistance; black oxide for wear; threaded inserts for quick adjustments.

Mounting methods:

Static: Epoxy bonding or bolted (elevator weights).

Dynamic: Shrink - fit (crankshafts) or integral machining (turbine rotors) to avoid loosening under vibration.

Sourcing & Quality Checks

Supplier qualifications:, powder metallurgy expertise, and material traceability (tungsten purity ≥99.9%).

Quality tests:

Density: Archimedes principle (target ±0.05 g/cm³).

Mechanical: Tensile strength (≥800 MPa) and hardness (≥30 HRC).

Non - destructive: Ultrasonic testing for internal defects.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU