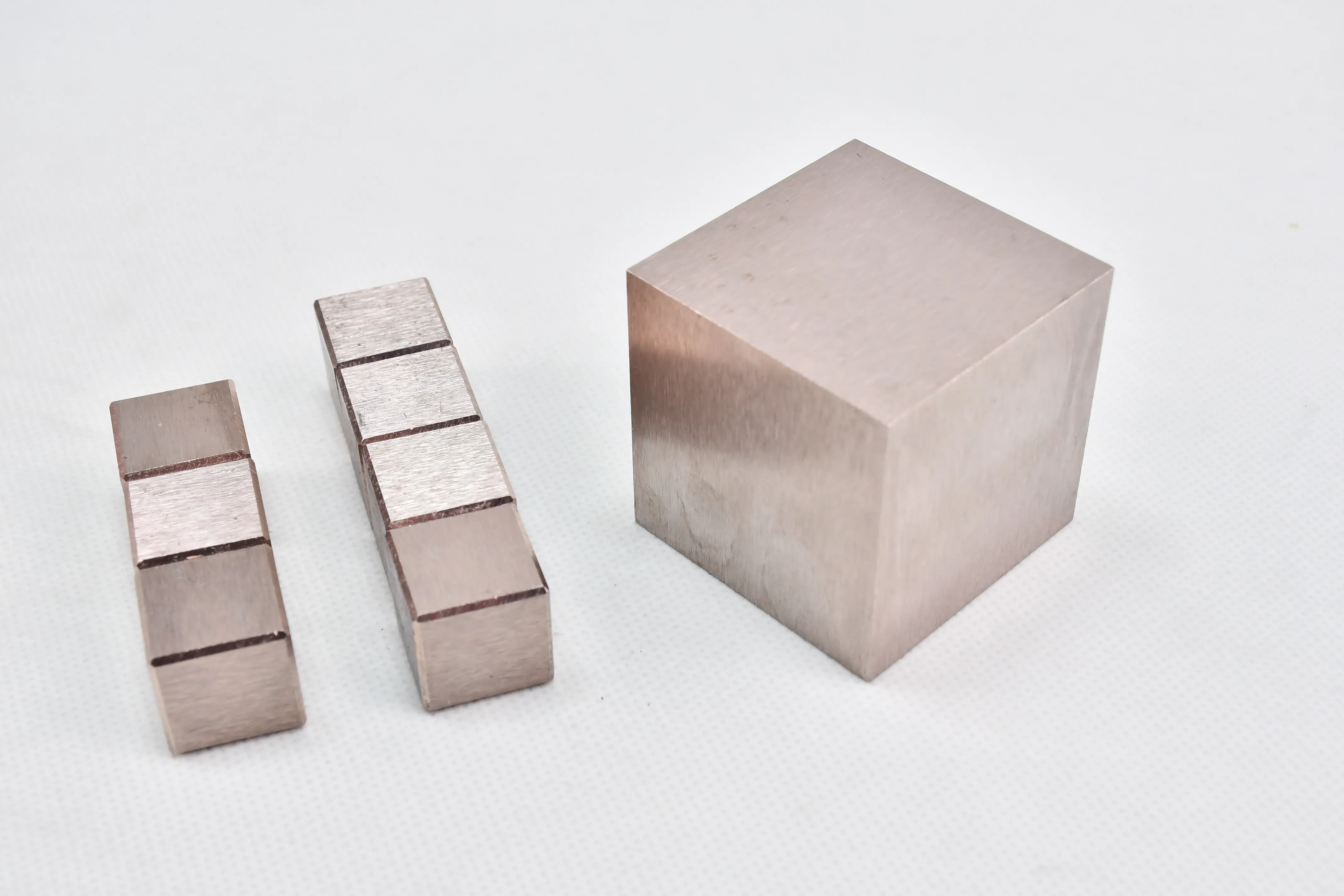

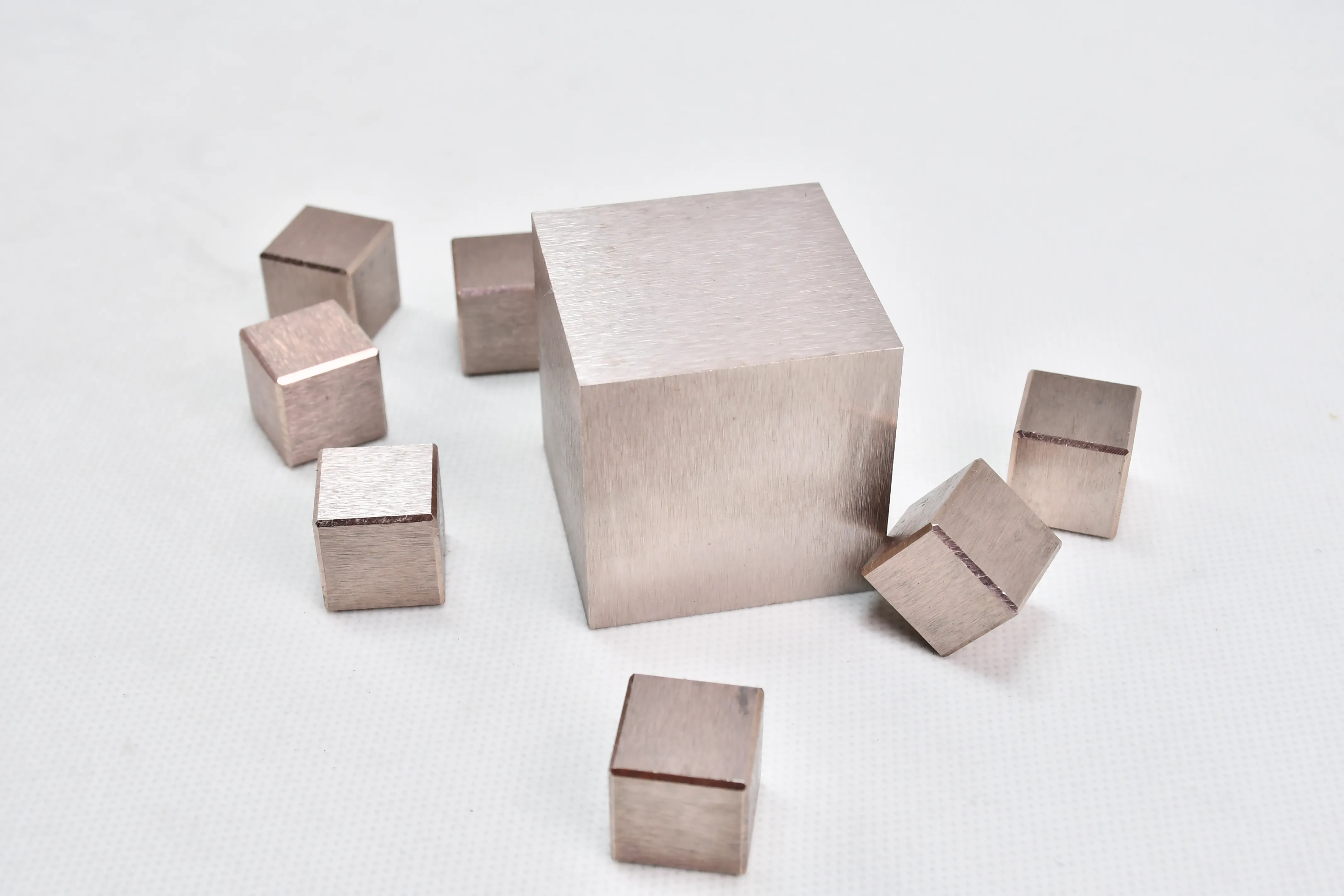

Tungsten copper alloy for electrical devices

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 10 Kilogram |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-086

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 50-90% Tungsten

Denstiy: 11.85-16.75 g/cm3

Surface: Polished

PACKAGING & DELIVERY

Selling Units : Kilogram

Package Type : Standard export packing

DESCRIPTION

Tungsten copper alloy is a kind of pseudo-alloy composed of tungsten and copper, which combines the high melting point, high hardness, and good arc resistance of tungsten with the excellent electrical and thermal conductivity of copper, making it widely used in electrical devices.

1. Core Properties for Electrical Applications

High electrical conductivity: The copper phase forms a continuous conductive network, ensuring low-resistance current transmission and reducing energy loss during operation.

Excellent arc erosion resistance: Under high-voltage and high-current conditions, the tungsten phase can resist the ablation of electric arcs, and the copper phase can quickly dissipate heat generated by arcs, avoiding material melting and deformation.

Good thermal conductivity: It can efficiently transfer the heat generated by electrical components during working, preventing overheating and failure of devices.

Adjustable performance: By changing the proportion of tungsten and copper (usually tungsten content is 50%–90%), the comprehensive properties of the alloy can be adjusted to meet the requirements of different electrical scenarios.

Specifications of WCu Alloy:

|

Item No. |

Chemical Composition (%) |

Mechanical properties |

||||||

|

CU |

Impurity |

W |

Density (g/cm3 ) |

Hardness HB |

RES( cm) |

Conductivity IACS/ % |

TRS/ Mpa |

|

|

CuW(50) |

50±2.0 |

0.5 |

Balance |

11.85 |

115 |

3.2 |

54 |

|

|

CuW(55) |

45± 2.0 |

0.5 |

Balance |

12.30 |

125 |

3.5 |

49 |

|

|

CuW(60) |

40±2.0 |

0.5 |

Balance |

12.75 |

140 |

3.7 |

47 |

|

|

CuW(65) |

35±2.0 |

0.5 |

Balance |

13.30 |

155 |

3.9 |

44 |

|

|

CuW(70) |

30±2.0 |

0.5 |

Balance |

13.80 |

175 |

4.1 |

42 |

790 |

|

CuW(75) |

25±2.0 |

0.5 |

Balance |

14.50 |

195 |

4.5 |

38 |

885 |

|

CuW(80) |

20±2.0 |

0.5 |

Balance |

15.15 |

220 |

5.0 |

34 |

980 |

|

CuW(85) |

15±2.0 |

0.5 |

Balance |

15.90 |

240 |

5.7 |

30 |

1080 |

|

CuW(90) |

10±2.0 |

0.5 |

Balance |

16.75 |

260 |

6.5 |

27 |

1160 |

2. Typical Applications in Electrical Devices

Switch and contact components: Used as contacts, contact tips, and arc-extinguishing pieces in high-voltage circuit breakers, load switches, and vacuum switches, which can withstand frequent on-off operations and arc impacts.

Electrode materials: Applied to electrodes of spot welding machines, resistance welding machines, and EDM (electrical discharge machining) equipment, relying on its high temperature resistance and conductivity to ensure stable welding and machining effects.

Heat dissipation and conductive parts: Used as heat sinks and conductive connectors in high-power electronic devices, which can simultaneously realize heat dissipation and current transmission functions.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU