Tungsten Alloy Fastener Screws – High-Density, High-Performance Fastening Solutions

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 50pcs |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-059

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 95% Tungsten

Denstiy: 18.1 g/cm3

Surface: Polised or Turned

PACKAGING & DELIVERY

Selling Units : Kilogram

Package Type : Standard export packing

DESCRIPTION

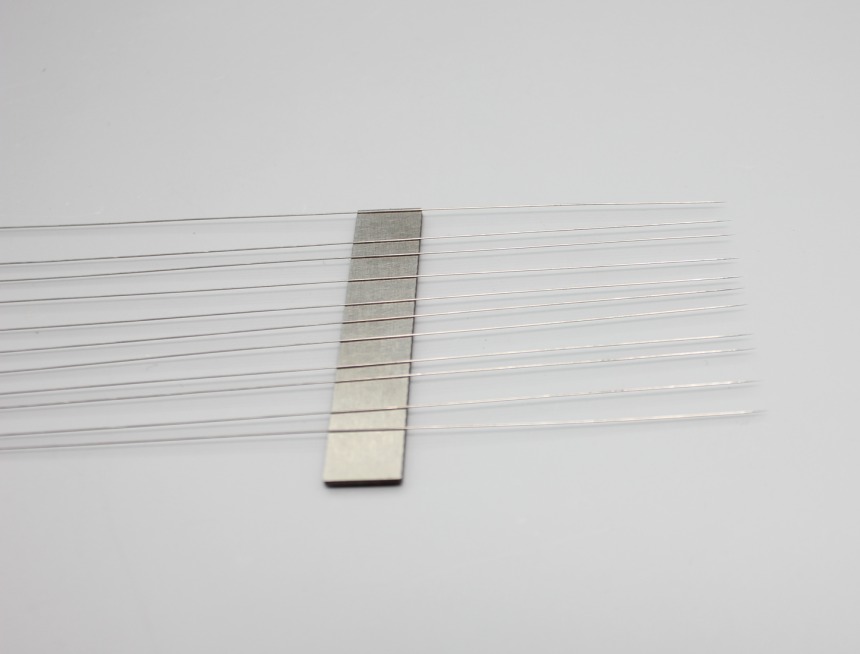

Tungsten alloy fastener screws are precision-engineered fastening components made from tungsten-nickel-iron (WNiFe) or tungsten-nickel-copper (WNiCu) alloys. Unlike conventional steel fasteners, they leverage tungsten's exceptional density (17.0-18.5 g/cm³) to provide maximum mass in minimal space, while maintaining high strength and durability for specialized applications.

Technical Specifications

|

Parameter |

Specifications |

|

Materials |

WNiFe (93%, 95%, 97% W), WNiCu (non-magnetic) |

|

Density |

17.0–18.5 g/cm³ (customizable) |

|

Strength Class |

Equivalent to ISO 898-1 Class 10.9–12.9 |

|

Thread Standards |

Metric (M2–M20), UNC/UNF, custom threads |

|

Head Styles |

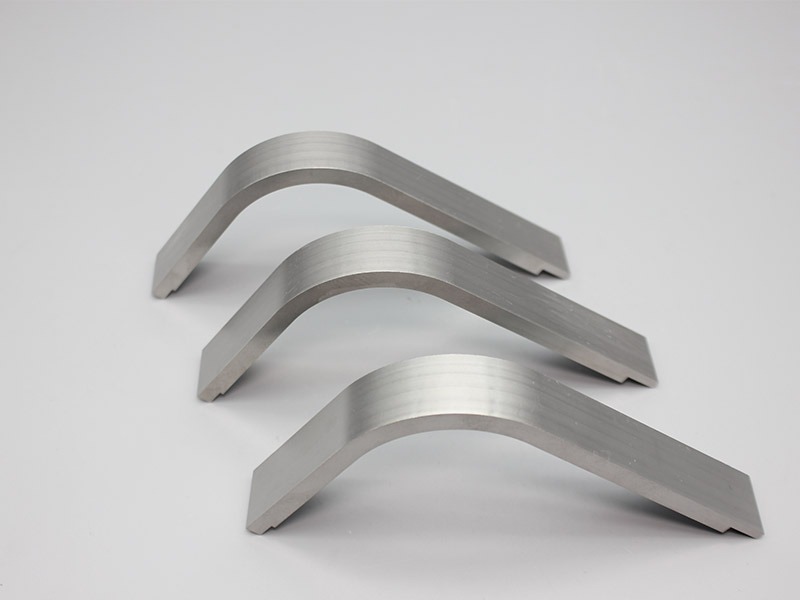

Hex socket, flat head, pan head, custom designs |

|

Surface Treatments |

Black oxide, nickel plating, passivation, DLC coating |

Production Process

Tungsten alloy screws cannot be manufactured by conventional metal forging (due to tungsten’s high hardness and brittleness), and are mainly produced by powder metallurgy + precision machining:

Powder preparation: Mix tungsten powder with nickel/iron/copper powder in a precise ratio, and homogenize via wet mixing.

Blank forming: Cold isostatic pressing (200–300 MPa) is used to press the mixed powder into a cylindrical blank matching the screw size.

Sintering: Sinter the blank in a hydrogen atmosphere at 1400–1600°C to form a dense tungsten alloy billet with a density of more than 98%.

Precision machining: Use CNC lathes and milling machines to process the billet into screws with standard threads (e.g., metric, imperial) and head types (hexagonal head, countersunk head, pan head). Thread precision can reach Grade 6–8.

Surface treatment: Plating or passivation is performed according to application requirements to improve corrosion resistance and wear resistance.

Quality inspection: Test dimensional accuracy, thread fit, tensile strength, and density to ensure compliance with application standards.

Application Fields of Tungsten heavy alloy

Tungsten alloy fastener screws are niche products targeted at special industrial scenarios, rather than general-purpose fastening:

Aerospace & aviation

Fastening counterweight components of aircraft engine rotors, helicopter rotor systems, and satellite attitude control devices. They fix the counterweight block while contributing to the overall balance of the equipment.

Fastening high-temperature components of rocket engine nozzles, withstanding the erosion of high-temperature gas and maintaining connection stability.

Nuclear & radiation equipment

Fastening shielding plates, detectors, and radioactive source containers in nuclear power plants, nuclear medicine equipment, and industrial non-destructive testing (NDT) devices. They not only fix components but also enhance local radiation shielding performance.

High-precision industrial equipment

Fastening high-speed rotating parts of centrifuges, precision grinders, and inertial navigation systems. Their high density and stability can reduce vibration caused by equipment operation.

Fastening heat sink components of high-power semiconductor devices, matching the thermal expansion coefficient of the heat sink to avoid component detachment due to thermal stress.

Military equipment

Fastening armor-piercing projectile components and missile guidance system parts, withstanding high-velocity impact and extreme environmental tests.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU