Tungsten alloy crucible

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 2pcs |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-095

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 97.5 - 98.7% Tungsten

Surface: polised or turned

PACKAGING & DELIVERY

Selling Units : Kilogram

Package Type : Standard export packing

DESCRIPTION

A tungsten alloy crucible is a high - performance container made of tungsten - based alloy materials, which is widely used in high - temperature and special - environment processes. Here is a detailed introduction:

Composition and Classification

- Composition: It is mainly made of high - purity tungsten (W≥99.95%) as the matrix, and may be doped with a small amount of rare - earth elements such as yttrium oxide (Y₂O₃) and lanthanum oxide (La₂O₃). For example, a rare - earth tungsten alloy crucible may contain 1.3 - 2.5% lanthanum oxide and 97.5 - 98.7% tungsten by mass percent.

- Classification by Manufacturing Process: It can be divided into sinter - formed, stamped - formed, spun - formed, and welded - formed crucibles. Among them, the sinter - formed crucibles are widely used and suitable for preparing large - sized crucibles; the stamped - formed and spun - formed crucibles are often used for manufacturing small - sized or thin - walled crucibles.

Performance Characteristics

- High - Temperature Resistance: Tungsten alloy crucibles have an extremely high melting point, reaching up to 3410°C. They can maintain good shape and mechanical properties in high - temperature environments above 2000°C, which is far beyond the temperature - bearing capacity of common ceramic and graphite crucibles.

- Chemical Stability: They have strong resistance to strong acids and alkalis and are not easily corroded. In a high - temperature and oxygen - rich atmosphere, the dense oxide film formed on the surface of the tungsten alloy can effectively slow down further oxidation, ensuring the stability of the crucible in harsh chemical environments.

- Good Thermal Conductivity: Tungsten alloy crucibles have relatively high thermal conductivity. For example, the thermal conductivity of tungsten is about 173 W/m·K. They can quickly and uniformly transfer heat in high - temperature processes, which is beneficial to ensure the uniform heating of materials and reduce product defects caused by uneven heat fields.

- High Mechanical Strength: These crucibles have high hardness and mechanical strength, and can still maintain high strength and good creep resistance at high temperatures, effectively avoiding deformation and failure caused by external forces or thermal stress.

-

Production Process

- Powder Preparation: High - purity tungsten powder and doping element powders are accurately weighed and mixed in a certain proportion. The particle size of the tungsten powder is usually in the range of 1.0 - 5.0 μm.

- Pressing: The mixed powder is subjected to isostatic pressing under a pressure of about 200 MPa for about 7 minutes to form a crucible blank.

- Sintering: The blank is sintered at a high temperature of about 2300°C for about 7 hours to improve its density and strength.

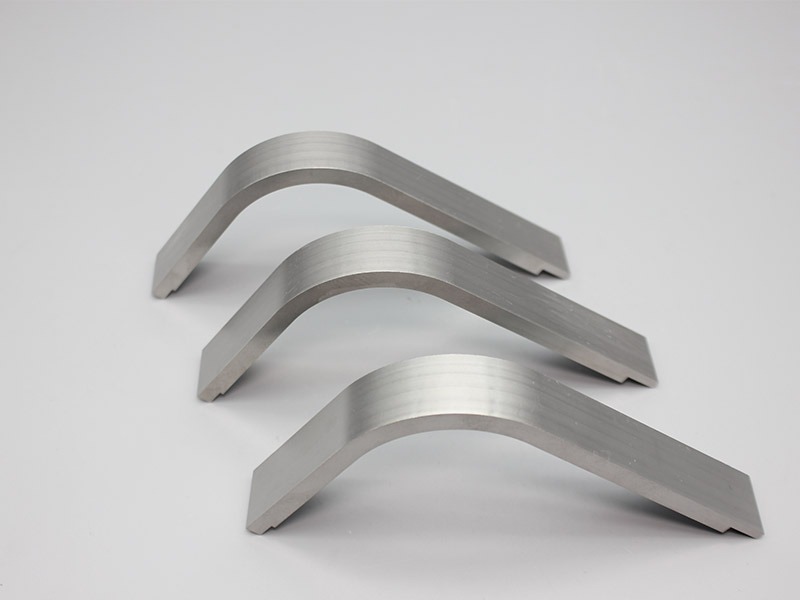

- Finishing: The sintered crucible is processed by turning, grinding, and other methods to meet the required size accuracy and surface roughness requirements.

Application Fields

- Crystal Growth: In the field of sapphire single - crystal growth, tungsten alloy crucibles can provide a stable high - temperature environment. Their low - thermal - expansion characteristics improve the thermal matching with the crystal, reducing internal stress in the crystal and improving the quality of the grown crystal.

- Rare - Earth Metal Smelting: They are used in vacuum induction furnaces for the melting and reduction of rare - earth oxides. Their strong corrosion resistance to rare - earth metal melts can ensure the purity of rare - earth metals and prolong the service life of the crucibles.

- Semiconductor and Photovoltaic Industry: In the preparation of high - purity semiconductor materials and photovoltaic materials, tungsten alloy crucibles can avoid contamination of materials due to their excellent chemical stability, ensuring the quality of products.

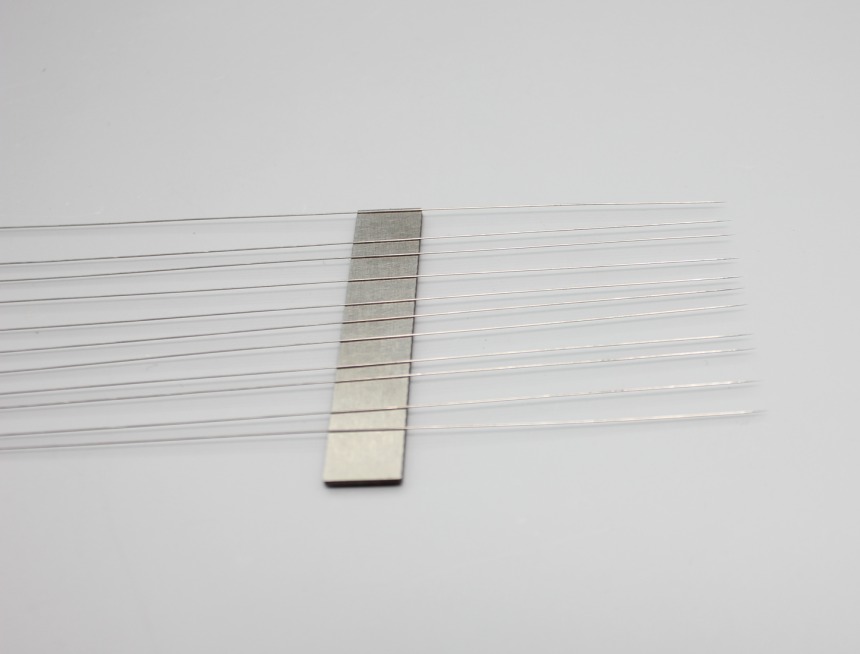

Appearance

Tungsten alloy crucibles are generally cylindrical, with a smooth and shiny surface. Their diameters range from 10 mm to 500 mm, and their heights range from 10 mm to 750 mm, with wall thicknesses of 8 mm to 20 mm. Different application scenarios may require crucibles of different shapes and sizes.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU