Tungsten Alloy Base – The Foundation of Precision and Stability

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 100pcs |

| Transportation: | Ocean,Air,Express |

Attributes

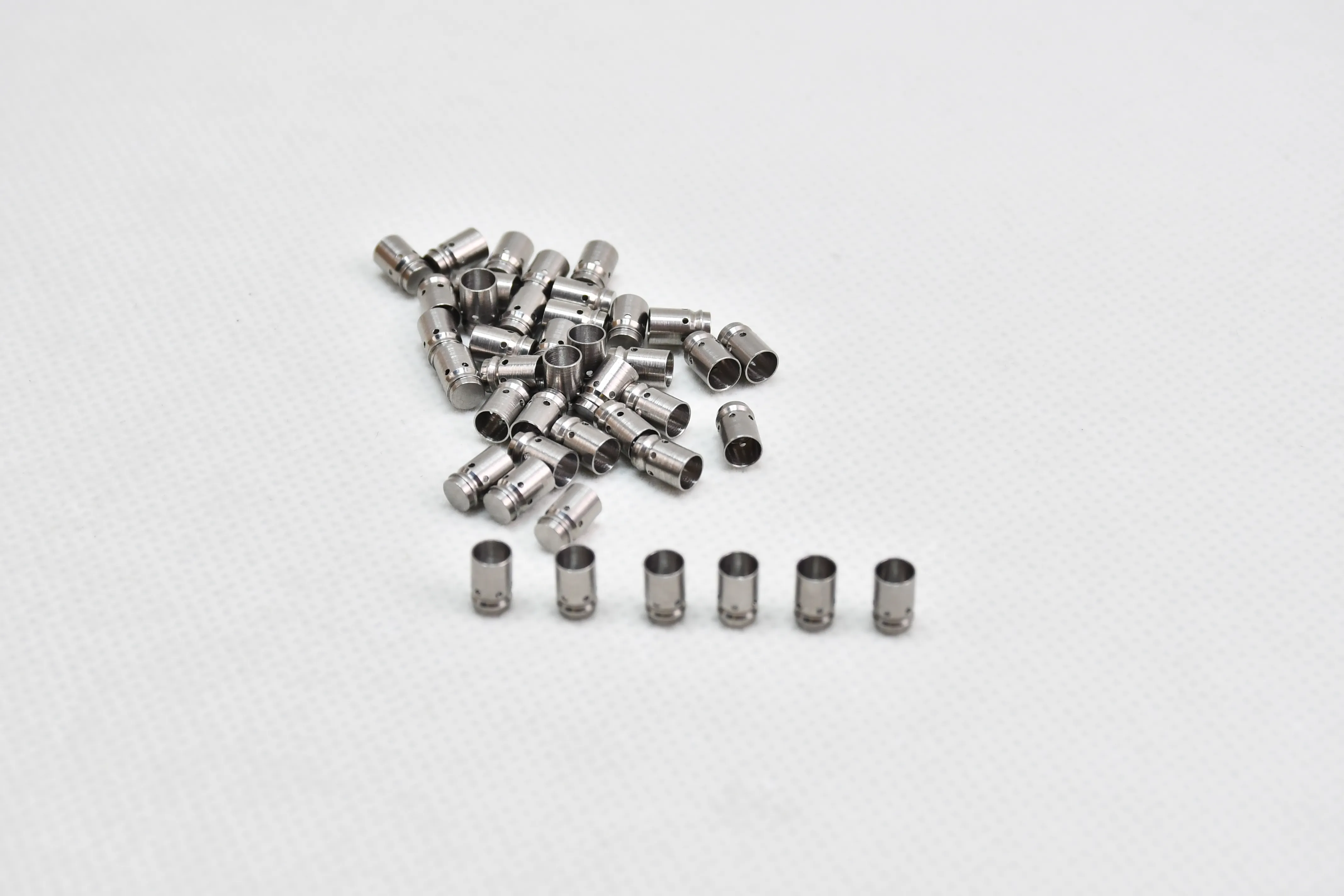

Model No.: JDTG-CM-035

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 95% Tungsten

Denstiy: 18.1g/cm3

Surface: Polished

PACKAGING & DELIVERY

Selling Units : PCS

Package Type : Standard export packing

DESCRIPTION

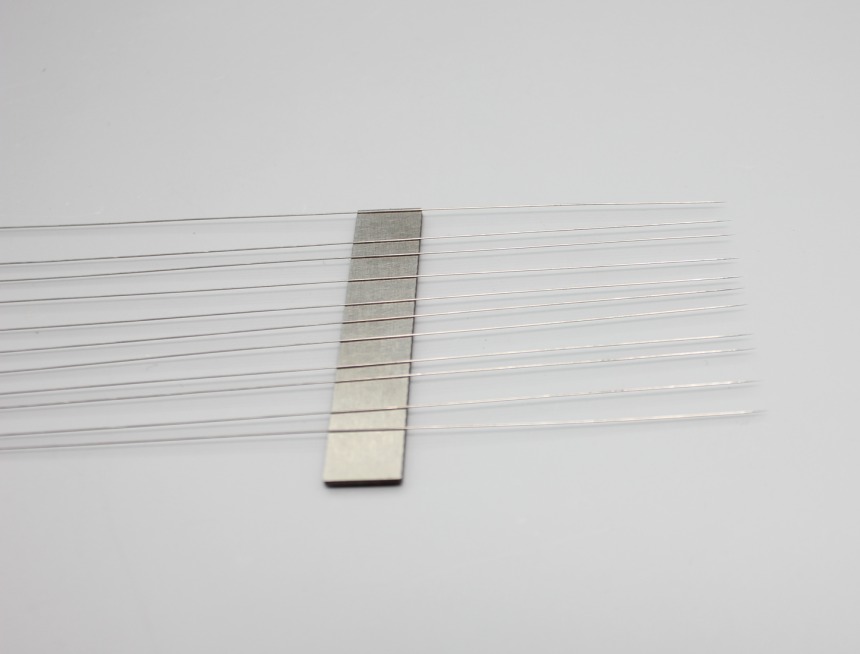

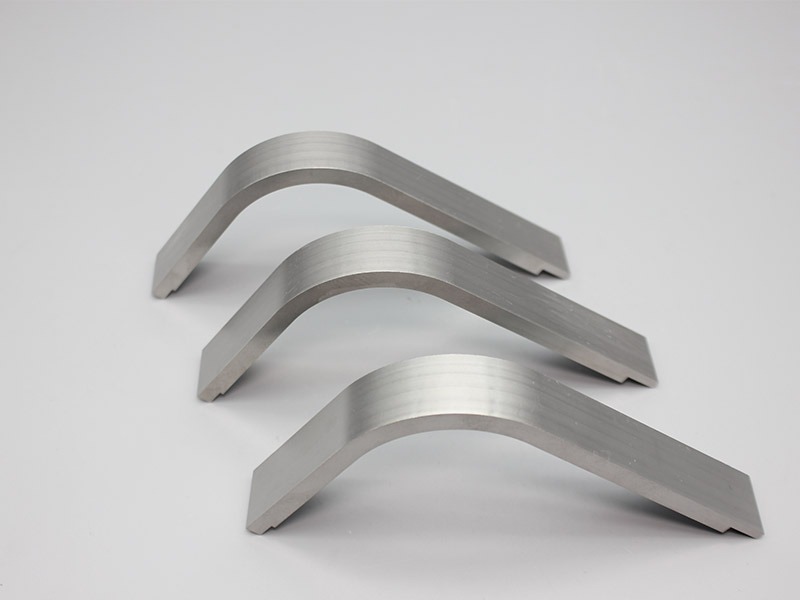

Tungsten alloy base refers to a high-performance substrate or base component made of high-density tungsten-based alloys (predominantly WNiFe or WNiCu systems, with tungsten content 90–97%). It is designed to provide stable support, high counterweight, radiation shielding, or thermal matching for functional components in special working environments. Its core value lies in combining ultra-high density, excellent mechanical stability, and corrosion resistance, making it ideal for scenarios where conventional metal bases (steel, aluminum) fail to meet requirements.

Core Performance Characteristics

Ultra-high density & counterweight capability

Density ranges from 15.8–18.75 g/cm³, 2–3 times that of steel. The base can achieve precise weight distribution in a small volume, which is critical for balancing high-precision equipment.

Excellent mechanical stability

It has high tensile strength (900–1100 MPa), hardness (HB 280–350), and creep resistance. It can maintain structural integrity under high load, vibration, or low-temperature conditions without deformation.

Good thermal & dimensional stability

The thermal expansion coefficient of tungsten alloy is low and matches well with ceramics, semiconductors, and refractory metals. This avoids thermal stress cracking between the base and the mounted components when subjected to extreme temperature changes.

Radiation shielding performance

Tungsten’s high atomic number (Z=74) enables the base to absorb X-rays, gamma rays, and other ionizing radiation, serving as both a support and a shielding component in radiation-related equipment.

Corrosion resistance

It does not rust or corrode in humid, saline, or mild acid-alkali environments. Surface plating (nickel, silver) can further enhance corrosion protection for harsh industrial environments.

Common Production Processes

Tungsten alloy bases are typically manufactured via powder metallurgy + precision machining, tailored to the required shape and size:

Powder mixing: Tungsten powder is uniformly mixed with nickel/iron/copper binder powder through wet mixing to ensure component homogeneity.

Blank forming: The mixed powder is pressed into a base blank under high pressure (200–300 MPa) using cold isostatic pressing (CIP) or die pressing.

Sintering: The blank is sintered in a hydrogen atmosphere at 1400–1600°C to form a dense tungsten alloy billet with a density of over 98%.

Precision machining: CNC milling, grinding, or drilling is used to process the billet into a base with precise dimensions, flatness, and mounting holes (threaded holes, positioning slots).

Surface treatment: Plating, passivation, or polishing is performed according to application needs to improve wear resistance, conductivity, or corrosion resistance.

Primary Industry Applications

1. Metrology & Precision Measurement

CMM & Vision System Bases: Unmatched rigidity minimizes deflection during probing

Laser Interferometer Platforms: Dampens floor vibrations for sub-micron accuracy

Calibration Weight Bases: Reference mass for high-precision scales

2. Semiconductor & Electronics Manufacturing

Photolithography Stage Bases: Thermal stability prevents alignment drift

Wafer Inspection Platforms: Vibration isolation for nanometer-scale imaging

Bonding/Assembly Tooling: Maintains alignment under thermal cycling

3. Medical & Scientific Imaging

CT/MRI Gantry Counterweights: Smooths rotation, reduces motor load

Gamma Camera Shields: Integrated shielding in detector mounts

Electron Microscope Stages: Minimizes specimen drift during long exposures

4. Aerospace & Defense

Inertial Guidance Platforms: Stable reference for accelerometers & gyros

Satellite Optical Benches: Maintains alignment through launch vibrations

Weapon System Mounts: Absorbs recoil, maintains zero

Selection & Specification Process

Step 1: Define Requirements

Primary function (stability, balancing, shielding, etc.)

Size constraints and weight budget

Environmental conditions (temperature, vibration, cleanliness)

Step 2: Material Selection

WNiFe: General purpose, highest density

WNiCu: Non-magnetic applications (MRI, electron optics)

Special alloys: For unique CTE or damping requirements

Step 3: Engineering Review

Finite element analysis (FEA) for stiffness optimization

Dynamic modeling for vibration performance

Thermal analysis for distortion prediction

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU