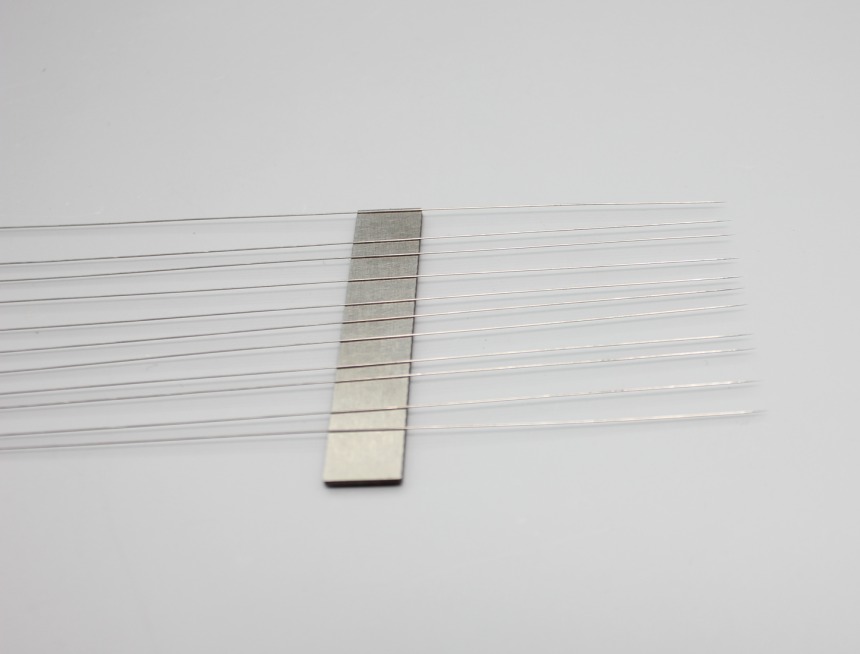

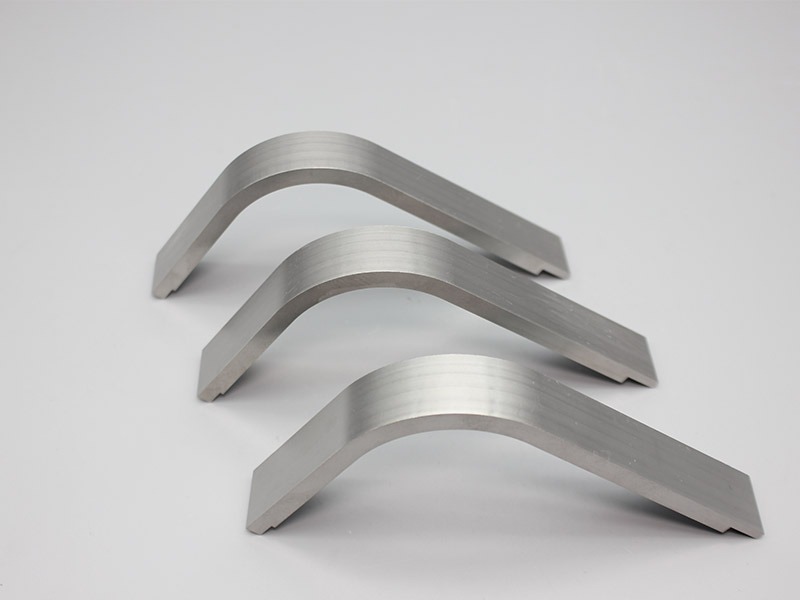

High-temperature-resistant tungsten alloy tubes

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 5pcs |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-CM-067

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 95% Tungsten

Denstiy: 18.1g/cm3

Surface: Polished

PACKAGING & DELIVERY

Selling Units : PCS

Package Type : Standard export packing

DESCRIPTION

Zhuzhou Jiuding’s tungsten alloy tubes (WNiFe/WNiCu, 90% 97% W) deliver high density (16.5~18.75g/cm³), exceptional radiation shielding, and precise machining, ideal for medical shielding, aerospace weighting, and industrial instrumentation. Below is the full technical specification, manufacturing process, quality control, and customization guide.

Core Material Grades & Key Properties

|

Grade |

Density (g/cm³) |

Tensile Strength (MPa) |

Elongation (%) |

Magnetic Property |

Shielding Performance |

Typical Applications |

|

90W Ni Fe |

16.5 17.0 |

750 900 |

15 25 |

Magnetic |

Standard |

Industrial NDT, general shielding |

|

95W Ni Fe |

18.0 18.3 |

800 950 |

12 20 |

Magnetic |

High |

Medical CT, nuclear instrument enclosures |

|

97W Ni Fe |

18.5 18.75 |

850 1000 |

8 15 |

Magnetic |

Ultra high |

Precision collimators, radiation therapy |

|

95W Ni Cu |

18.0 18.2 |

780 920 |

10 18 |

Non magnetic |

High |

MRI-compatible shielding, electronic devices |

Standard & Customizable Specifications

|

Parameter |

Standard Range |

Tolerance |

Surface Finish |

|

Outer Diameter (OD) |

3~150mm |

±0.05~±0.1mm |

Ra≤0.8μm (CNC), Ra≤0.2μm (grinding) |

|

Inner Diameter (ID) |

1~140mm |

±0.05~±0.1mm |

Ra≤1.6μm (as~machined) |

|

Wall Thickness |

0.5~10mm |

±0.05mm |

— |

|

Length |

50~500mm |

±0.2mm |

— |

|

Special Shapes |

Straight tubes, stepped tubes, flanged tubes |

Custom per drawing |

— |

Manufacturing Process Flow (Precision Control)

Powder Preparation: Tungsten powder (purity ≥99.95%) + Ni/Fe/Cu binder; mixed with oxygen content ≤50ppm, uniformity deviation ≤1% (oxygen‑nitrogen analyzer + sampling metallography).

Forming:

Die pressing: For standard straight tubes (OD≥10mm, wall thickness≥1mm), tolerance ±0.1mm.

CIP (200‑300MPa): For thin‑walled/complex tubes (OD<10mm, wall thickness<1mm), better density uniformity.

MIM: For micro‑tubes (OD<3mm, ID<1mm), high precision.

Sintering: Hydrogen/vacuum sintering at 1380‑1500℃; theoretical density ≥99.5%; grain size controlled at 10‑30μm (metallographic microscope).

Finishing: CNC turning/milling, grinding, threading; dimensional tolerance up to ±0.02mm (CMM‑inspected); surface treatment (passivation, Ni‑plating) optional.

Application‑Specific Optimization

Medical Shielding Tubes: 95W/97W‑Ni‑Fe; wall thickness 1‑5mm; 100% ultrasonic NDT + gamma attenuation testing; lead equivalent report provided.

Aerospace Weighting Tubes: 90W‑Ni‑Fe; dimensional tolerance ±0.02mm; dynamic balance testing; density deviation ≤0.05g/cm³.

Industrial NDT Tubes: 90W‑Ni‑Fe; cost‑effective die pressing; surface passivation for corrosion resistance; tolerance ±0.1mm.

Customization Workflow

Provide 2D/3D drawing + specs (grade, OD/ID/wall thickness, length, tolerance, surface finish, quantity).

Jiuding delivers material recommendation, process plan, and quote within 3 hours.

Sampling: 3‑5 days for small samples (≤5kg), cost 1.5‑2.0× base price (deductible for bulk ≥50kg).

Mass production: 15‑20 days (bulk ≥50kg); urgent orders available with 10%‑20% premium.

Shipment: With inspection report + certificate; full traceability via batch number.

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU