90WCu Tungsten copper alloy

| Payment Type: | T/T |

| Incoterm: | CIF,FOB,Express Delivery,EXW,FCA |

| Min. Order: | 2pcs |

| Transportation: | Ocean,Air,Express |

Attributes

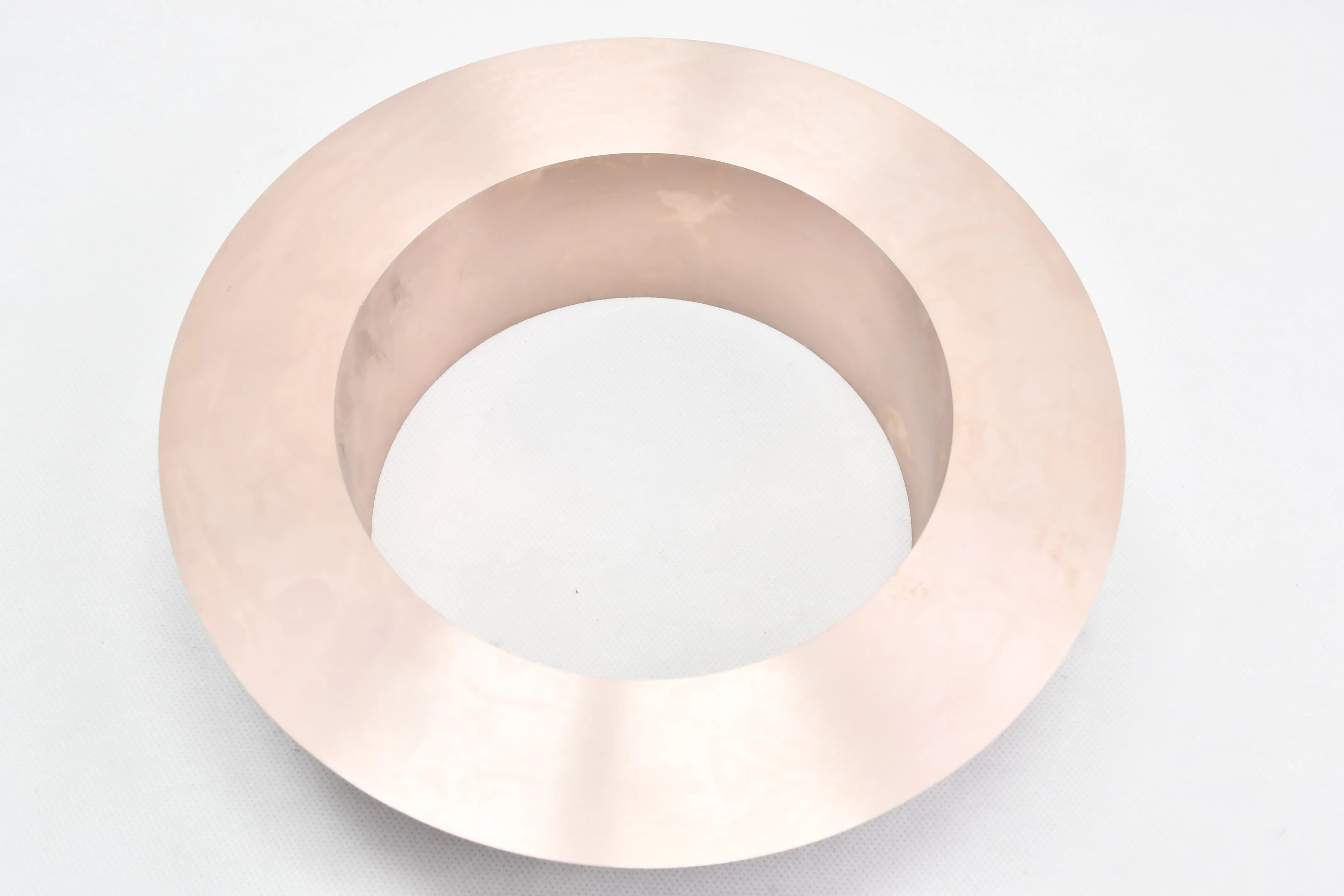

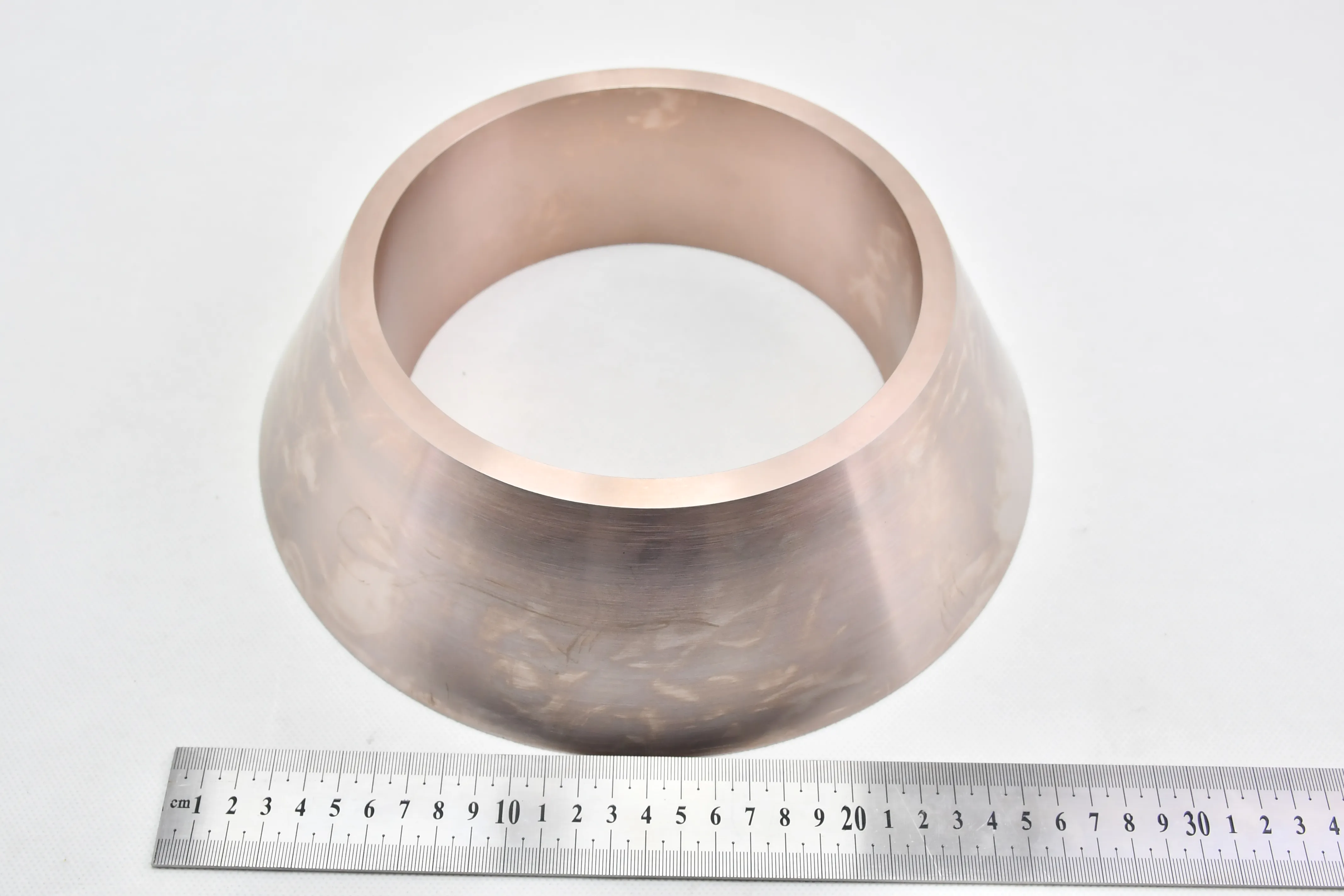

Model No.: JDTG-CM-052

Brand: ZZJD

Place Of Origin: China

Size: Custom-made

Material: 90% Tungsten

Denstiy: 16.7 g/cm3

Surface: Polished or turned

PACKAGING & DELIVERY

Selling Units :PCS

Package Type : Standard export packing

DESCRIPTION

Tungsten Copper Alloy – The Ultimate High-Performance Composite Material

90WCu Tungsten Copper Alloy refers to a tungsten-copper composite material with a tungsten content of 90 wt% and copper content of 10 wt%. It combines the high melting point, high hardness, and excellent arc resistance of tungsten, with the good electrical conductivity, thermal conductivity, and plasticity of copper. It is a typical pseudo-alloy (no intermetallic compounds are formed between tungsten and copper, and the two phases are uniformly distributed in a mechanical mixture).

Key Performance Characteristics

Basic Physical Properties

Property Typical Value

Density ~16.7 g/cm³

Thermal Conductivity ~180 W/(m·K)

Electrical Conductivity ~45% IACS

Melting Point ~1083°C (copper phase melting point, tungsten remains stable below 3410°C)

Hardness (HB) ~220–250

Core Functional Advantages

Excellent Electrical & Thermal Conductivity:

Copper phase forms a continuous network to conduct electricity and heat rapidly, which can quickly dissipate heat generated by high current and arc erosion.

Strong Arc Erosion Resistance:

Tungsten phase has high hardness and high melting point, which can resist the ablation of electric arcs; the copper phase can "self-heal" the surface by melting and volatilizing to take away heat, reducing arc adhesion.

Low Thermal Expansion Coefficient:

The thermal expansion coefficient is matched with semiconductor materials (such as silicon, gallium arsenide) and ceramics, which can avoid thermal stress cracking in high-temperature environments.

Good Machinability:

Compared with pure tungsten, the copper phase improves the toughness of the alloy, making it easy to process into complex shapes through cutting, drilling, and grinding.

Production Process

90WCu alloy is mainly prepared by powder metallurgy technology:

Powder Mixing: Mix 90% tungsten powder (particle size 1–5 μm) and 10% copper powder uniformly by wet mixing.

Press Forming: Press the mixed powder into a blank under high pressure (200–300 MPa) by cold isostatic pressing.

Sintering: Sinter the blank in a hydrogen atmosphere at 1200–1400°C to form a porous tungsten skeleton, and the copper phase fills the pores to form a dense alloy.

Secondary Processing: Perform infiltration, hot forging, or machining to optimize the density and dimensional accuracy of the alloy.

Typical Application Fields

90WCu alloy is widely used in electrical, electronic, and aerospace fields due to its excellent electrical and thermal properties:

Electrical Contact Materials

Used for contacts and electrodes of high-voltage switches, circuit breakers, and vacuum interrupters. It can withstand the impact of high current and arc, and has a long service life (far better than pure copper or brass contacts).

Heat Sink Materials for Semiconductors

As heat sinks and substrate materials for high-power semiconductor devices (e.g., IGBT modules, microwave tubes). It can quickly transfer the heat generated by the device to the radiator, ensuring the stable operation of the semiconductor.

Aerospace & Military Components

Thruster Nozzles

Used for rocket and missile engine nozzles, which can withstand high-temperature gas erosion and quickly dissipate heat.

Electromagnetic Pulse (EMP) Devices: As electrode materials for high-power pulse generators, it can bear instantaneous high current discharge.

Welding Electrodes

Used for resistance welding electrodes and spot welding electrodes, especially suitable for welding high-conductivity materials (e.g., copper, aluminum alloys). It has good wear resistance and thermal stability.

Notes

90WCu alloy is not suitable for high-temperature oxidation environments (copper phase is prone to oxidation above 300°C), so it needs to be protected by plating (e.g., nickel plating, silver plating) in atmospheric environments.

Compared with other WCu alloys (e.g., 70W30Cu, 80W20Cu), 90WCu has higher hardness and arc resistance, but slightly lower electrical and thermal conductivity.

|

Code No. |

Chemical Composition % |

Mechanical properties |

||||||

|

CU |

Impurity |

W |

Density (g/cm3 ) |

Hardness HB |

RES( cm) |

Conductivity IACS/ % |

TRS/ Mpa |

|

|

CuW(50) |

50±2.0 |

0.5 |

Balance |

11.85 |

115 |

3.2 |

54 |

|

|

CuW(55) |

45± 2.0 |

0.5 |

Balance |

12.30 |

125 |

3.5 |

49 |

|

|

CuW(60) |

40±2.0 |

0.5 |

Balance |

12.75 |

140 |

3.7 |

47 |

|

|

CuW(65) |

35±2.0 |

0.5 |

Balance |

13.30 |

155 |

3.9 |

44 |

|

|

CuW(70) |

30±2.0 |

0.5 |

Balance |

13.80 |

175 |

4.1 |

42 |

790 |

|

CuW(75) |

25±2.0 |

0.5 |

Balance |

14.50 |

195 |

4.5 |

38 |

885 |

|

CuW(80) |

20±2.0 |

0.5 |

Balance |

15.15 |

220 |

5.0 |

34 |

980 |

|

CuW(85) |

15±2.0 |

0.5 |

Balance |

15.90 |

240 |

5.7 |

30 |

1080 |

|

CuW(90) |

10±2.0 |

0.5 |

Balance |

16.75 |

260 |

6.5 |

27 |

1160 |

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU